Reactor: PPR (Parallel Pressure Reactor)

Reactor volume: 50 ml - 300 ml

Number of reactors: 2 - 6

Pressure: -1.0 (FV) to +150 bar

Temperature: -20 °C to +300 °C

Material: stainless-steel, Hastelloy®, tantalum, PTFE inliner

Researchers at ETH Zurich, in collaboration with Buchi, have made a significant breakthrough in chemical plastics recycling.

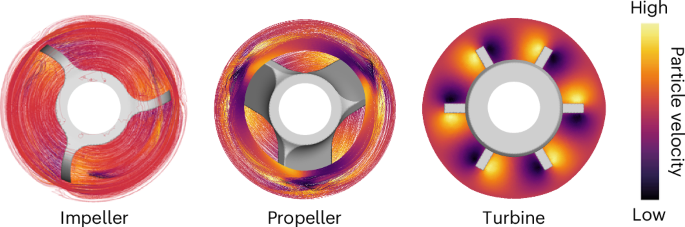

Leveraging Buchi’s PPR (Parallel Pressure Reactor) system, they demonstrated that precise control over stirring parameters is crucial for optimizing the recycling process.

This innovative research introduced a new criterion that enhances mixing performance and catalyst effectiveness for the treatment of polyethylene and polypropylene.